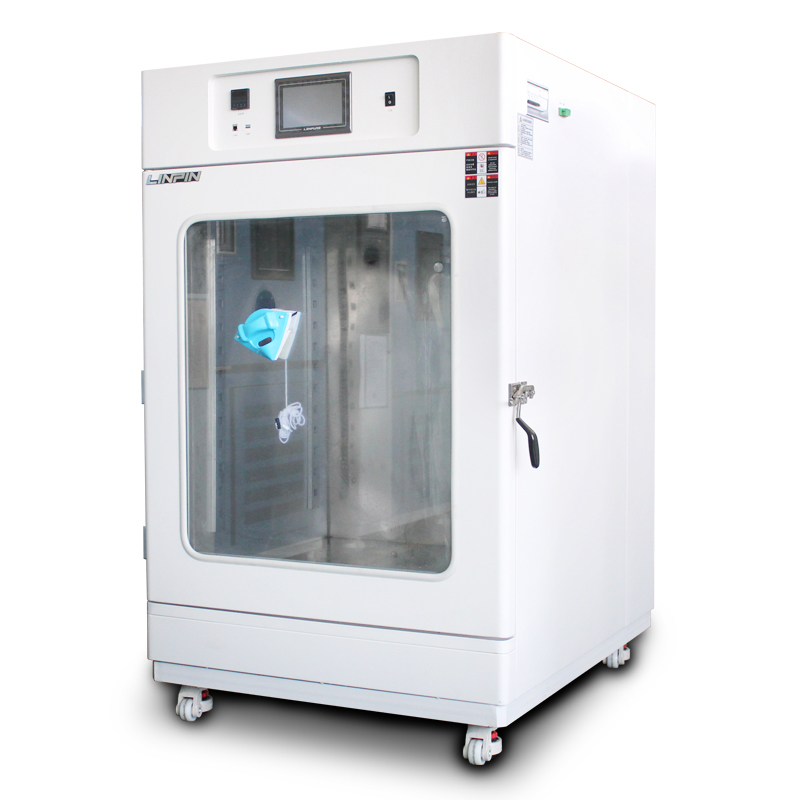

ISO 9001 auditors love this: Blast Drying Oven with Uniformity

Author:LINPIN Update Time:2025-09-30 Source:LINPINIn the rigorous landscape of modern industrial and research applications, the consistency and reliability of thermal processing equipment are not merely advantageous—they are imperative. This white paper examines the critical role of temperature uniformity, specifically the achievement of a ±1°C tolerance, within blast drying ovens. Such precision is a cornerstone of compliance with international quality management standards, most notably 9001. We will delve into the engineering principles, the direct impact on product quality and process validation, and the operational excellence that makes a blast drying oven with ±1°C uniformity an indispensable asset for any quality-driven organization. This document serves to articulate why this specific performance metric is a primary focal point for astute quality auditors and a definitive marker of manufacturing prowess.

1. Introduction: The Paramountcy of Precision in Thermal Processing

The blast drying oven, a workhorse in laboratories and production facilities worldwide, is tasked with a deceptively simple objective: to apply controlled, uniform heat to a product. Applications span a vast spectrum, from drying sensitive pharmaceutical compounds and sterilizing laboratory glassware to curing coatings on aerospace components and conditioning materials for precise weight measurement. The common denominator across all these applications is that the outcome is critically dependent on the thermal environment's homogeneity.

A deviation of even a few degrees Celsius from the setpoint, or a gradient across the workspace, can lead to catastrophic results. In pharmaceuticals, it can compromise the stability of an active ingredient. In polymer curing, it can result in inconsistent material properties. In food testing, it can invalidate moisture content analysis. It is this inherent risk that elevates the specification of temperature uniformity from a simple datasheet number to a fundamental pillar of Quality Management Systems (QMS). For auditors schooled in the principles of ISO 9001, evidence of controlled and validated processes is the ultimate proof of an organization's commitment to quality. A blast drying oven certified to maintain ±1°C uniformity is not just a piece of equipment; it is a testament to a culture of precision and a powerful tool for risk mitigation.

2. Deconstructing ISO 9001: Why Auditors Scrutinize Equipment Calibration and Control

ISO 9001:2015, the international standard for quality management systems, is built upon the principle of consistent delivery of products and services that meet customer and regulatory requirements. Its core tenets include a process approach, evidence-based decision making, and a relentless focus on risk-based thinking. When an auditor assesses a laboratory or production area, their gaze falls upon equipment with several key questions in mind:

- Clause 7.1.5: Monitoring and Measuring Resources: Are the equipment used for verification and validation activities calibrated and maintained to ensure valid results? Can the organization provide evidence that the oven performs as specified under actual working conditions?

- Clause 8.5.1: Control of Production and Service Provision: Are the processes that directly affect product quality carried out under controlled conditions? This includes using suitable equipment that is properly maintained. Temperature uniformity is a primary controlled condition for thermal processes.

- Clause 8.5.2: Identification and Traceability: For processes where variability could impact quality, is the process validated? A validated oven process, proven to deliver ±1°C uniformity, provides this traceability and assurance.

An oven that boasts ±1°C uniformity directly addresses these clauses. It provides the tangible, quantifiable evidence an auditor seeks. It demonstrates that the organization has invested in a tool capable of minimizing process variation, a primary source of quality defects. It shifts the conversation from "we hope the oven is uniform" to "we have validated data proving the oven is uniform."

3. The Engineering Marvel Behind ±1°C Uniformity: More Than Just a Heating Element

Achieving a temperature uniformity of ±1°C across the entire workspace is not a trivial feat. It is the result of sophisticated engineering that addresses the fundamental challenges of heat transfer: stratification, conduction, and convection. Standard ovens may exhibit gradients of ±3°C to ±5°C or worse, which is unacceptable for critical applications. The journey to ±1°C involves a multi-faceted approach:

3.1. Advanced Airflow Dynamics: The Principle of Forced Convection

The term "blast" in blast drying oven is key. Unlike gravity-convection ovens that rely on passive, natural air movement (leading to hot air rising and significant stratification), blast ovens employ a powerful motorized blower. This system creates a high-velocity, horizontal or vertical laminar airflow that circulates the heated air vigorously and consistently throughout the chamber. This forced convection disrupts thermal stratification, ensuring that heat is distributed evenly to all samples, regardless of their location on the shelves.

3.2. Precision Air Guide Systems: Eliminating Dead Zones

The mere presence of a fan is insufficient. The air must be intelligently guided. High-precision ovens feature strategically designed air ducts, baffles, and plenums. These components work in concert to direct the airflow uniformly across the entire cross-section of the workspace, eliminating "dead zones" or corners where temperature can deviate. The design is often validated through Computational Fluid Dynamics (CFD) simulations long before the first unit is built, optimizing the path of every molecule of air for perfect homogeneity.

3.3. Superior Insulation and Sealing

Thermal losses through the oven walls and door can create significant gradients, with areas near the insulation being cooler than the center. Ovens designed for ±1°C uniformity utilize high-density mineral wool or fiberglass insulation of substantial thickness. Furthermore, the door seal is a critical component. A robust, double-lipped silicone gasket ensures an airtight seal, preventing ambient air from infiltrating the chamber and disrupting the delicate thermal equilibrium.

3.4. Intelligent, Multi-Zone Heating and Control

The heating elements and temperature sensors are integral to this precision. Instead of a single, large heating element, these ovens often employ multiple, strategically placed heating zones. These are managed by a sophisticated microprocessor-based PID (Proportional-Integral-Derivative) controller. The PID algorithm doesn't just turn the heat on and off; it continuously calculates the difference between the setpoint and the actual temperature (measured by a high-accuracy PT100 sensor) and adjusts the power to the heaters in a smooth, anticipatory manner to prevent overshoot and maintain stability. The multi-zone control allows the system to compensate dynamically for minor fluctuations in different parts of the chamber.

4. The Tangible Value Proposition: How ±1°C Uniformity Drives Operational Excellence

The investment in a high-precision blast drying oven yields returns that permeate every aspect of an organization's operations, translating engineering excellence into concrete business benefits.

4.1. Unassailable Product Quality and Consistency

This is the most direct benefit. When every sample in a batch is subjected to the exact same thermal profile, batch-to-batch reproducibility is guaranteed. A pharmaceutical company can be confident that every vial of product has been dried identically. A materials science lab can trust that the mechanical properties of their test specimens are consistent. This eliminates a major variable, allowing scientists and engineers to have full confidence in their data and products.

4.2. Enhanced Process Validation and Regulatory Compliance

For industries regulated by bodies like the FDA, EMA, or ASTM, process validation is mandatory. Validating a thermal process with an oven that has a ±5°C uniformity is a complex, often frustrating endeavor, requiring extensive testing to define a "worst-case" location. In contrast, an oven with ±1°C uniformity dramatically simplifies validation. The entire usable space becomes a "golden zone," reducing the scope of testing, saving countless hours of labor, and producing a validation report that is robust and easily defensible during audits.

4.3. Accelerated Research and Development (R&D)

In R&D, time is a critical resource. Inconsistent results caused by poor oven performance can lead to weeks or months of wasted effort chasing phantom variables. A precision oven acts as a reliable partner in innovation, providing trustworthy data from the outset. It accelerates the path from discovery to commercialization by ensuring that experimental results are accurate and attributable solely to the variables intentionally being tested.

4.4. Reduction in Waste and Rework

Scrap and rework are the enemies of profitability and efficiency. A failed batch of product due to uneven curing or drying represents a direct financial loss in materials, labor, and energy. By virtually eliminating temperature non-uniformity as a failure mode, these ovens significantly reduce waste and the need for costly rework, improving the bottom line and promoting sustainable practices.

4.5. Long-Term Operational Reliability and Reduced Downtime

Ovens engineered to such a high standard are invariably built with superior components—heavy-duty blowers, high-grade stainless steel interiors, and robust controllers. This inherent durability translates to greater mean time between failures (MTBF), reduced maintenance requirements, and less unplanned downtime, ensuring that critical production and research schedules are met reliably.

5. The Audit-Ready Laboratory: Demonstrating Compliance with Confidence

When an ISO 9001 auditor enters a facility, their goal is to verify the effectiveness of the QMS. Presenting a blast drying oven with documented ±1°C uniformity provides a powerful narrative of control. The organization can present a comprehensive package that includes:

- Factory Calibration Certificate: Traceable to national standards (e.g., NIST, DAkkS), confirming the ±1°C uniformity specification.

- On-Site Validation Protocol and Report: Data from periodic performance qualifications (PQ) conducted according to a standardized protocol (e.g., using a multi-point temperature mapping system with data loggers placed throughout the chamber). This proves the oven maintains its performance in the user's specific environment and under typical load conditions.

- Preventive Maintenance Records: Logs showing regular maintenance of the blower, seals, and sensors, demonstrating proactive control over the equipment's condition.

- Standard Operating Procedures (SOPs): Clear documentation on the correct use and loading of the oven to maintain the validated state.

This collection of documents transforms the oven from a black box into a fully characterized and controlled asset. It allows the quality manager to state with authority: "We have identified temperature control as a critical process parameter. We have invested in a tool capable of exceeding the required precision. We continuously monitor and maintain its performance. Here is the evidence." This level of preparedness is what auditors love to see.

6. Conclusion: An Investment in Certainty

In the final analysis, a blast drying oven with ±1°C temperature uniformity is far more than an incremental improvement over standard models. It represents a philosophical commitment to excellence. It is a decisive step away from process variability and towards absolute control. The engineering required to achieve this level of performance is complex, but the value it delivers is simple and profound: certainty.

For the researcher, it means trustworthy data. For the production manager, it means predictable output. For the quality professional, it means an audit trail built on rock-solid evidence. And for the ISO 9001 auditor, it is a clear and unambiguous indicator of an organization that understands the direct correlation between precise process control and superior quality outcomes. In a world where quality is the ultimate differentiator, such precision is not a luxury; it is the gold standard.